PRODUCT

Low Refractive Index Resin

Low Refractive Index Resin

Coating Resin (P/S)

Single Coating Resin

Ribbon Matrix Resin

UV Curable Ink

Resin for Display

High Refractive Index Resin

Ribbon Fiber OEM

Resin for 3D Printer

EFiRON®, XPC-Series

High Temperature & High Power Application

In recent high power fiber lasers, both high temperature resistance and high glass ahehesion are required to ensure laser operation stability and reliability.

EFiRON® XPC is combination of our patented Fluorine polymer technology, to meet the growing customer needs in high power fiber laser industry and thermoplastic coated fiber manufactureres

EFiRON® XPC can provide:

- high temperature resistance

- high adhesion to silica glass surface

- high water-proof

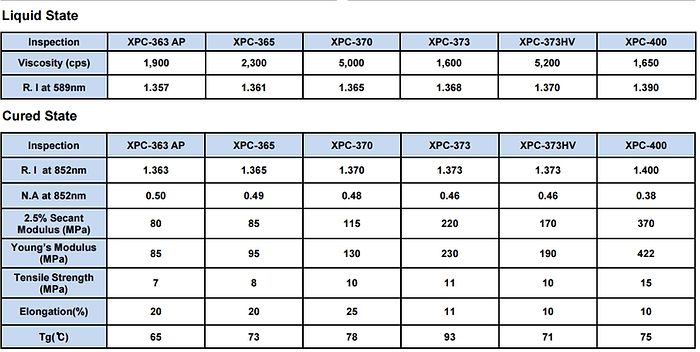

Along with flexible control of optical, and mechanical properties.

EFiRON® XPC can be used as a cladding in high power fiber lasers, and high power delivery fibers, and recoating material for high power optical fibers.

EFiRON® XPC can be used as a cladding of a plastic cladding fiber (PCF) that is further coated with thermoplastic at high temperature.

Detailed properties can be further tailored upon customers' requests.

Fospia shares some of the customers' feedbacks for XPC!

EFiRON® XPC has the fastest curable properties(0.5J/cm2).

EFiRON® XPC has high modulus allowing and high temperature high power(400~1,000 watt) with a proper cooling device.

EFiRON® XPC has low attenuation(20~30% lower than major competition) in high pressure, high temperature and corrosive environment.

EFiRON® XPC has excellent high power resistance, showing 1.5 times higher maximum pump than other competing polymer resins.

EFiRON® XPC is suitable for high power single coating application due to no stickiness on the surface after cured, resulting in no need to overclad the fiber.

EFiRON® XPC-373 was referenced in a customer's research paper : the estimated pump power density on the surface of the XPC-373 cladding exceeded 630 W/mm, the highest value ever reported and 1.5 ~7 times higher than that of five other coating methods tested. The long-term reliability of the device was tested for 170 hours of continuous operation.

.png)